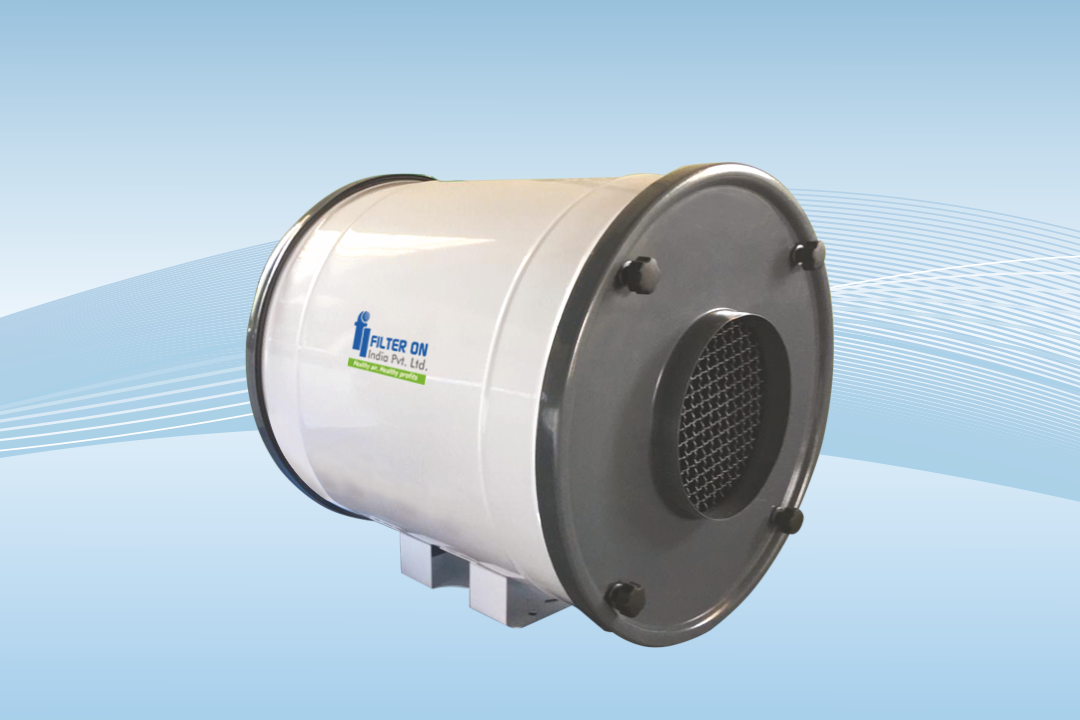

Industrial Mist Collector

Product Details:

- Orientation Centrifugal Type

- Usage & Applications Maintly coolant mist filtration suitable for water soluble coolants for VMC, HMC, CNC lathes etc. and component cleaning machines.

- Efficiency 1 MICRON 98.00% COLLECTION EFFICENCY

- Product Type Centrifugal Type Coolant Mist Collector

- Material MILD STEEL ALKALINE RESISTANCE COAT

- Noise Level 73 DB db

- Capacity 400-2100 CMH in 4 Models m3/hr

- Click to View more

Industrial Mist Collector Price And Quantity

- 1 Unit

Industrial Mist Collector Product Specifications

- 1.5 HP Horsepower (HP)

- Centrifugal Type

- Centrifugal Type Coolant Mist Collector

- 12 Months

- 73 DB db

- 40 Kilograms (kg)

- 400-2100 CMH in 4 Models m3/hr

- 475mm OD x 400mm length Meter (m)

- Maintly coolant mist filtration suitable for water soluble coolants for VMC, HMC, CNC lathes etc. and component cleaning machines.

- 1 MICRON 98.00% COLLECTION EFFICENCY

- MILD STEEL ALKALINE RESISTANCE COAT

Industrial Mist Collector Trade Information

- 10 Unit Per Month

- 30 Days

- Wooden Packaging and Plastic Wrapping

- All India

- ISO-9001:2015, CE

Product Description

Filter On Indias Centrifugal Mist Collectors are eminently suitable for applications in machining operations which include

Machining Centers

Lathes

Grinding

These devices are particularly effective for facilities experiencing low to moderate levels of mist

Applications

The collectors are not limited to managing Water Soluble Coolants for assorted machinery such as VMC HMC CNC lathes etc but are also advantageous for component cleaning machines

We offer four distinct models of the Centrifugal Mist Collectors with capacities ranging from 400m3hr to 2100 m3hr to wit

C7

C21

C29

C35

Operational Methodology

The contaminated air saturated with mist is drawn into the apparatus through a highvelocity rotor The centrifugal force generated consolidates minuscule particles which coalesce into larger droplets of coolant The aggregated coolant is then directed through a discharge mechanism and reinstated into the CNC machines system

Depending on specific parameters such as the application in question the concentration of mist and the type of coolant we apply a diverse array of filters to achieve the utmost efficiency in performance

Advantages

Compact design

Facile installation process

Straightforward operation and maintenance routine

Key Application In Industry

Machining centers HMC VMC

Component Cleaning Washing machines

Surface grinders

Wire drawing

Stamping presses

Screw machines and

Roll mill operations

Key Benefits

Improved working environment

Improved air quality

Reduced mistrelated hazards

Application Industrial

Condition New

Standard First Class

Operation Semi Automatic

FAQs of Industrial Mist Collector

Q What is the efficiency of the Industrial Mist Collector

A The efficiency of the Industrial Mist Collector is 100

Q What is the material used for construction

A The Industrial Mist Collector is made of stainless steel

Q What is the intended usage of this product

A This product is designed for industrial use

Q Is the Industrial Mist Collector available in different sizes

A Yes it is available in various sizes to suit different industrial needs

Q What type of business offers this product

A This product is offered by a manufacturer and supplier

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+